From OEM to Co-create: The Story Behind Everything Presence Lite – An Advanced and Smart mmWave Sensor

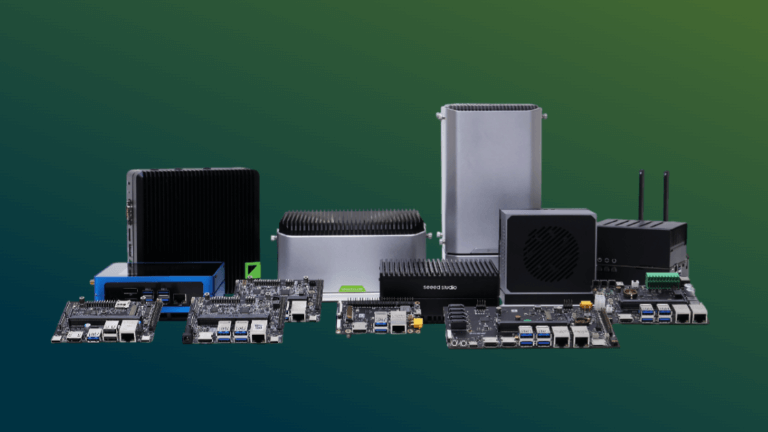

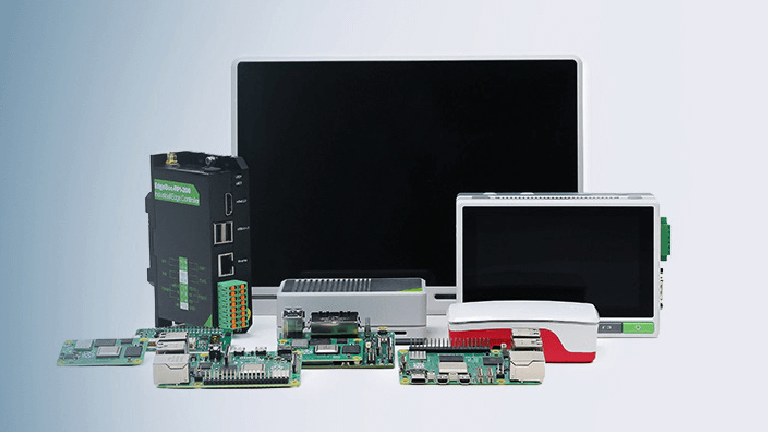

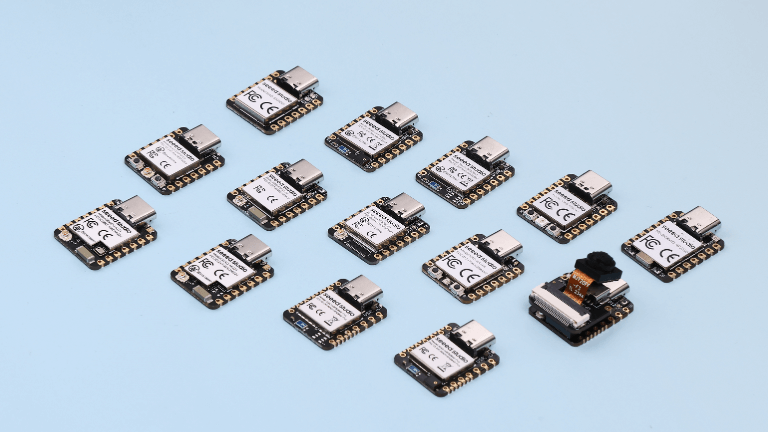

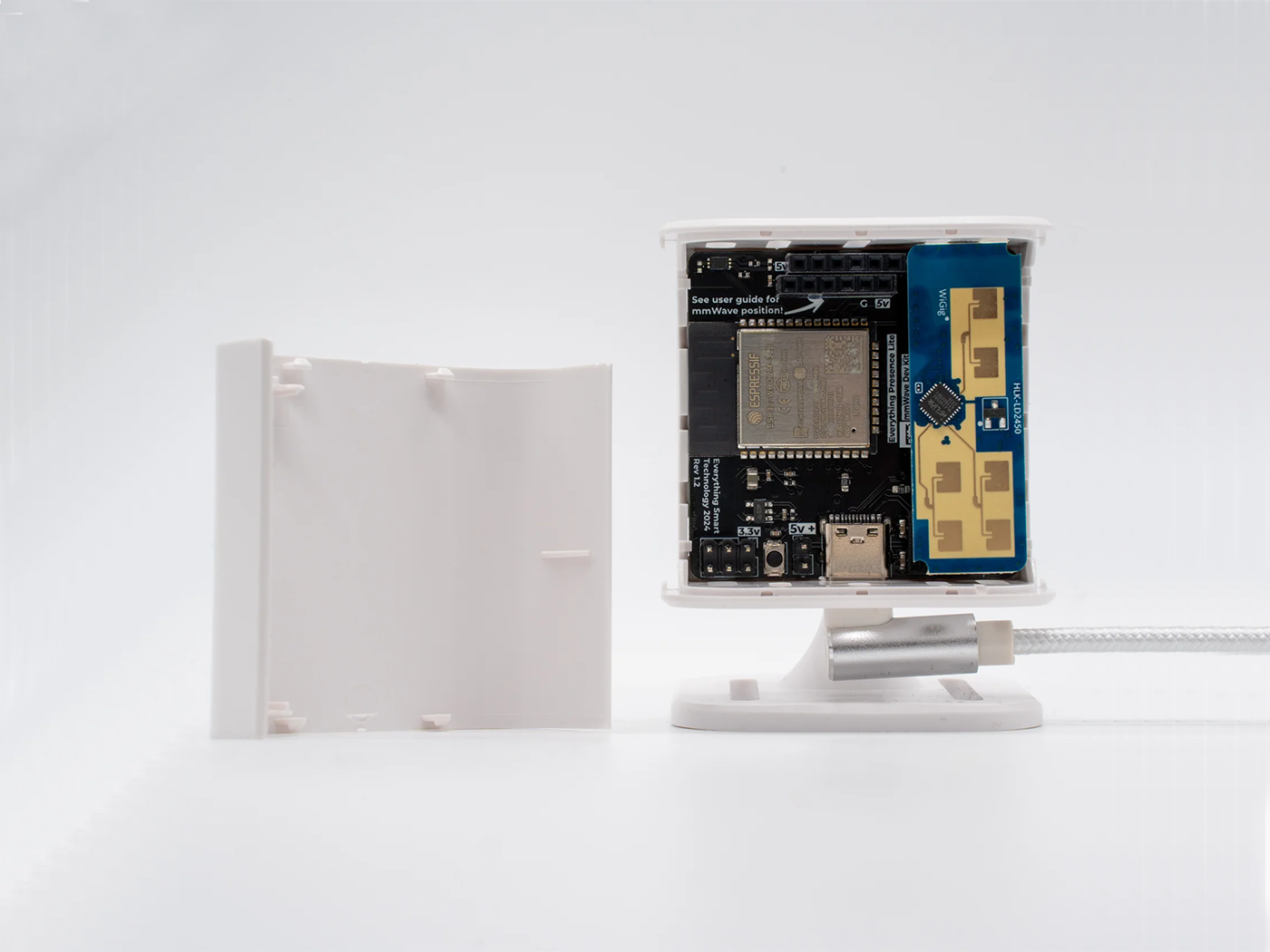

What is Everything Presence Lite? Designed and developed by Everything Smart Home and manufactured with Seeed Studio, the Everything Presence Lite is an ESP32-based mmWave presence sensor designed to ...